Ready mixed concrete is a fundamental material in the construction industry, providing the strength and durability required for buildings, bridges, roads, and many other structures. One critical aspect of producing high-quality concrete is ensuring the precise measurement of its components. Ready mixed concrete plants are equipped with expensive precision weighing equipment to achieve this goal. This article will delve into why such precision is necessary, focusing on the impact of accurate measurements on the strength and workability of concrete.

The Importance of Precision in Concrete Production

1. Consistency in Mix Design

Concrete is composed of cement, water, aggregates (sand, gravel, or crushed stone), and sometimes admixtures. The proportions of these components significantly affect the concrete’s properties. Precision weighing equipment ensures that each batch of concrete has the exact proportions specified in the mix design. Consistency in mix design is crucial for maintaining the uniformity of concrete quality, which is essential for the structural integrity of constructions.

2. Strength of Concrete

The strength of concrete is primarily determined by the water-cement ratio and the quality of aggregates. An imbalance in the mix can lead to either weak or overly brittle concrete. Precision weighing ensures that the correct amount of each component is used, preventing variations that could compromise the strength. For example:

- Water-Cement Ratio: Too much water can weaken the concrete by increasing its porosity, while too little water can make it difficult to work with and achieve proper compaction.

- Cement Content: Accurate measurement of cement ensures that the concrete achieves its intended strength. Too much or too little cement can alter the concrete’s compressive strength.

3. Workability of Concrete

Workability refers to how easily concrete can be mixed, placed, and finished. It is influenced by the water content and the aggregate sizes. Precision weighing equipment helps maintain the desired workability by ensuring the correct proportions of water and aggregates:

- Water Content: Proper water content is essential for achieving the right consistency. Too much water can lead to segregation and bleeding, while too little water can make the concrete difficult to handle.

- Aggregate Proportions: The size and distribution of aggregates affect the concrete’s flowability and compaction. Precise weighing ensures a balanced mix that enhances workability without compromising strength.

The Role of Precision Weighing Equipment

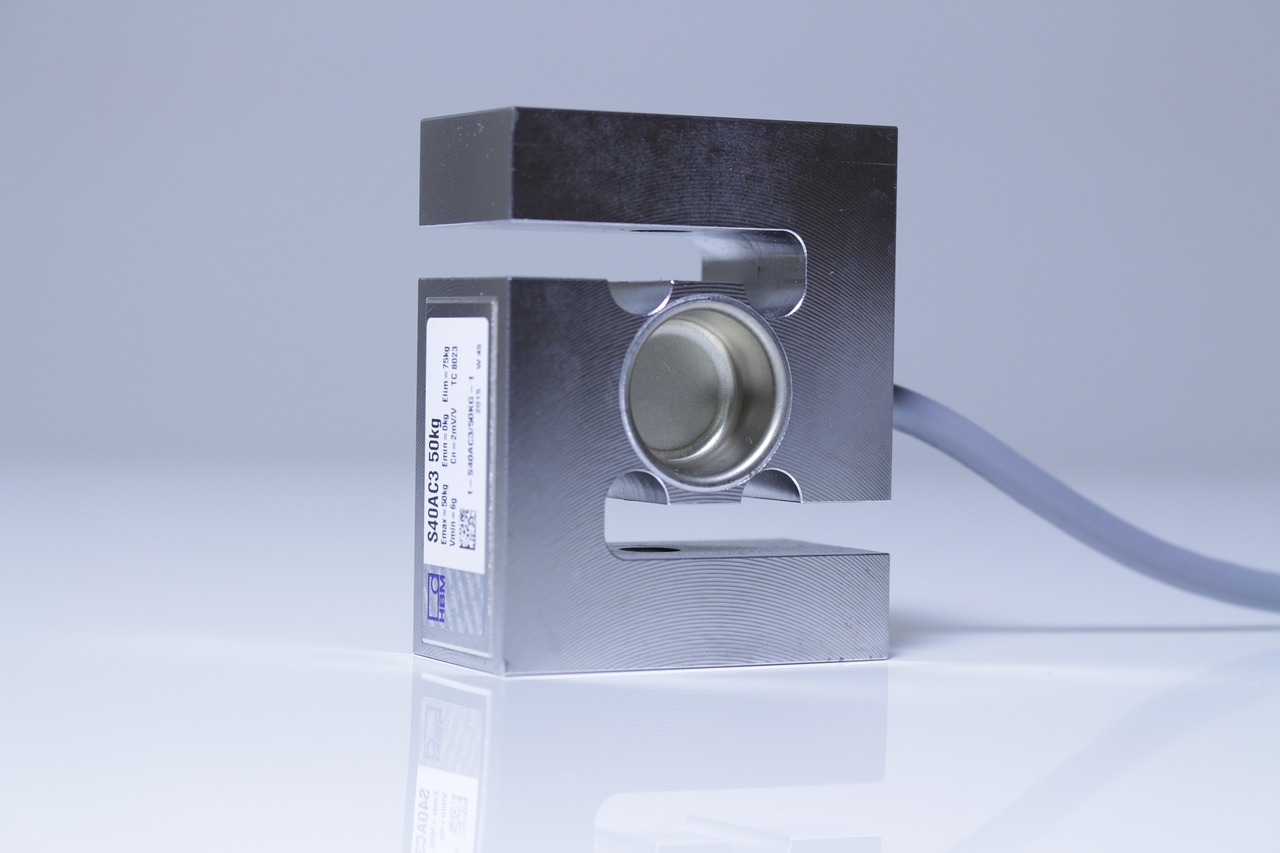

1. Load Cells and Scales

Ready mixed concrete plants use load cells and scales to weigh the components accurately. These devices are calibrated to detect even the smallest deviations in weight. This precision is crucial for maintaining the integrity of the mix design and ensuring that every batch meets the required specifications.

2. Automated Batching Systems

Modern concrete plants often use automated batching systems that integrate precision weighing equipment. These systems control the entire mixing process, from measuring the components to mixing and delivering the final product. Automation reduces human error, enhances efficiency, and ensures that the concrete produced is of consistent quality.

3. Quality Control and Assurance

Precision weighing equipment is a vital part of the quality control process in concrete production. Regular calibration and maintenance of these devices ensure their accuracy and reliability. Quality control measures, such as routine testing of concrete samples, help verify that the mix proportions are correct and that the concrete meets the required standards.

Benefits of Precision Weighing in Concrete Production

1. Enhanced Structural Integrity

Accurate measurement of concrete components leads to a consistent mix design, which is essential for the structural integrity of constructions. Buildings and infrastructure projects rely on concrete’s strength and durability. Precision weighing helps prevent issues such as cracking, spalling, and premature failure, which can result from improper mix proportions.

2. Cost Efficiency

While precision weighing equipment is expensive, it can lead to significant cost savings in the long run. Consistent concrete quality reduces the need for repairs and maintenance, prolonging the lifespan of structures. Additionally, precise measurements minimize waste and optimize the use of materials, contributing to overall cost efficiency.

3. Compliance with Standards and Regulations

The construction industry is governed by strict standards and regulations to ensure safety and quality. Precision weighing equipment helps concrete plants comply with these standards by producing concrete that meets specified requirements. Compliance with regulations not only ensures safety but also enhances the credibility and reputation of concrete producers.

Challenges and Considerations

1. Initial Investment and Maintenance

The high cost of precision weighing equipment can be a barrier for some concrete producers. However, the long-term benefits, such as improved quality and cost savings, often outweigh the initial investment. Regular maintenance and calibration are essential to keep the equipment functioning accurately and reliably.

2. Technological Advancements

Advancements in technology continue to improve the accuracy and efficiency of precision weighing equipment. Innovations such as digital load cells, automated batching systems, and real-time monitoring are enhancing the precision and reliability of concrete production. Staying updated with these advancements can help concrete plants maintain their competitive edge.

Precision weighing equipment is essential for ready mixed concrete plants to produce high-quality concrete with the desired strength and workability. Accurate measurement of concrete components ensures consistency in mix design, which is crucial for the structural integrity of constructions. Despite the high cost, the benefits of precision weighing, including enhanced quality, cost efficiency, and compliance with standards, make it a necessary investment for concrete producers. As technology continues to advance, the accuracy and efficiency of precision weighing equipment will only improve, further supporting the production of superior concrete for the construction industry.